Balancing the forks of a 12" LX200 ACF

|

|

|

The forks from the factory were out of lateral balance by almost THREE POUNDS. Way too much for my taste. Time to go to work. Click Here to download a construction drawing in PDF format |

|

|

First thing to do was to find a place to put the weight. This hadn't been a problem on my old Classic with the open forks, but now we have to go poking about in the innards to find a place.

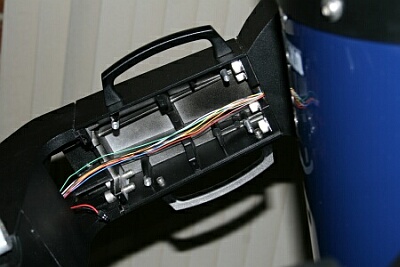

Four small screws let you remove the battery box, and one set screw holds the back cover in place. It slides out once you back out the retaining set screw. |

|

Plenty of room behind the battery box in the corner |

Back view of available space |

|

I had a lead brick lying about, a souvenir from my glow-in-the-dark days of growing up around the nuclear industry. I cut a chunk off one end, and started carving it into something that would fit. |

|

Starting and ending points |

Built in two pieces A main block (intentionally light) and a trim block |

Assembled weight before trimming |

Trimming for final balance |

| A few trial fits to check for progress and a few passes through the mill brought the final weight to what it needed to be: 2 lb. 11 oz. |

|

Finished balance weight Note slot for wire clearance |

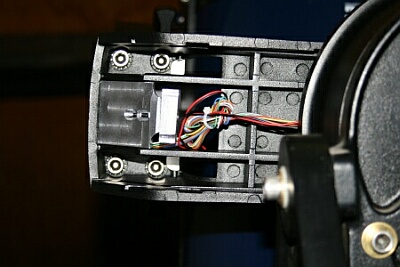

Bolted in place - It fits! |

View from the bottom |

View from inside the fork |

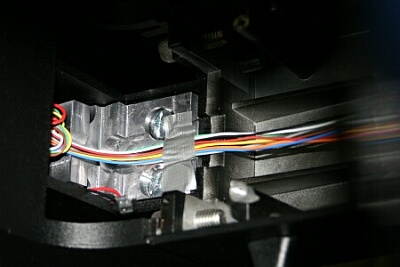

Wires taped in place for safety |

Wider view of fork and taped wires |

Put the plastic back on - We're done! |

|