| Knob Tweaker - Collimation Tool For Bob's Knobs or Things Similar... |

|

| I like Bob's Knobs. They sure beat fumbling with an allen wrench, and they will get you into the ball park quickly. Then comes the hard part: Precise collimation demands the smallest possible turn of the adjusting screws, and it's VERY difficult to avoid over-shooting the "sweet spot". This little jewel clamps on to a Bob's Knob and stays put. Move the end a millimeter or so at a time, and achieve incredibly tiny movements of the screw. At 0.5 oz., it isn't heavy enough to move the screw on its own. Let it hang while you wait for the jiggles to settle out so you can see what you just did. | |

Knob Tweaker front view |

All you need to know about using it |

|

Simple and dirt-cheap to make - Here's what you need to know: Lightweight wood. Spruce or Pine will do fine. This one's 1" wide, 8" long (a bit longer than it really needs to be for a 12" Meade), and a little less than a quarter of an inch thick. Thickness should be a tad thicker than the knob you want to turn. |

|

Back side view |  The part that grabs the knob |

| Start by carving out a space that slips (just a little loosely) over the knob. Cut away as much wood as you dare along the middle to keep the weight down, and cut notches where the shaft will go. The covers over the slots are 0.015" aluminum, glued in place. You could also use cardboard, plastic sheet, anything you like to keep the shaft in place. |

|

|  |

| A nylon screw and a "Threaded Insert" (hardware store items) make up the clamp. Coat the screw with grease or Vaseline or something similar so epoxy won't stick to it, thread it half-way through an insert as shown in the photo, and epoxy the insert in place. |

|

Threaded Insert and Nylon Screw (8-32) |  Insert epoxied in place. |

| When the epoxy has cured, remove the screw (you greased it, right? - it will come out...) clean the grease off and use it as one of your parts to make something like this: |

|

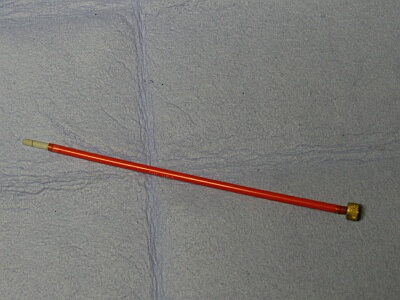

Nylon screw - plastic tube - thumb screw | The plastic tube came from a hobby shop. It's quite rigid in torsion, and it's a tight fit around an 8-32 screw. (Brand name: Sullivan - the tube is part of a model control rod called "Golden Rod") I put one end in boiling water to soften the plastic, drove the nylon screw into it, and repeated the process to get an 8-32 thumb screw into the other. When satisfied, cut the head off the nylon screw and thread it into the insert. Done! |

| This is as simple (and easy) as it gets. I've used this little tool for years, and it always goes with me, stuffed in a slot cut in the foam of my scope case. | |